- NEEQ: 837355

- To be a global leader in overmolding protection industry.

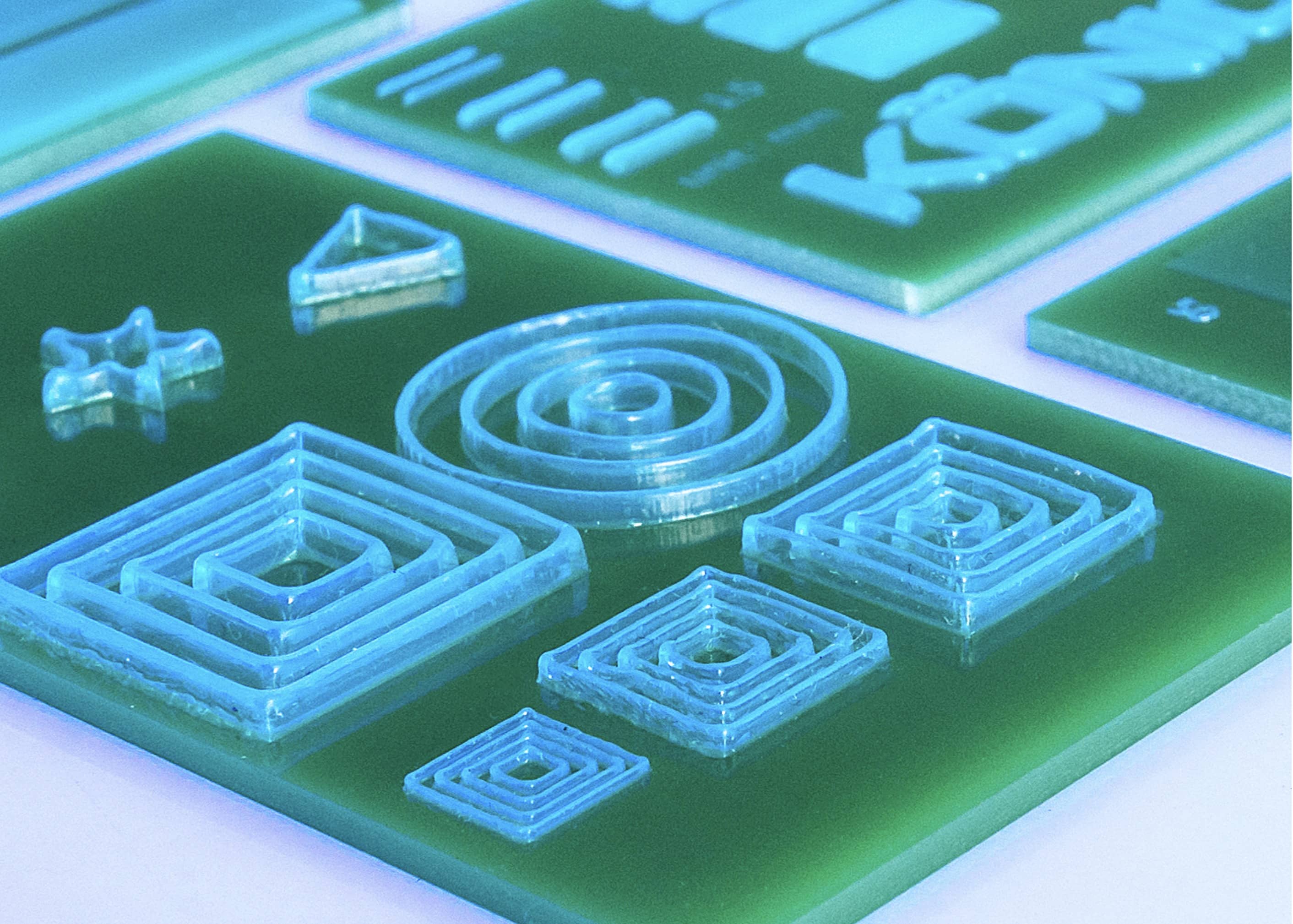

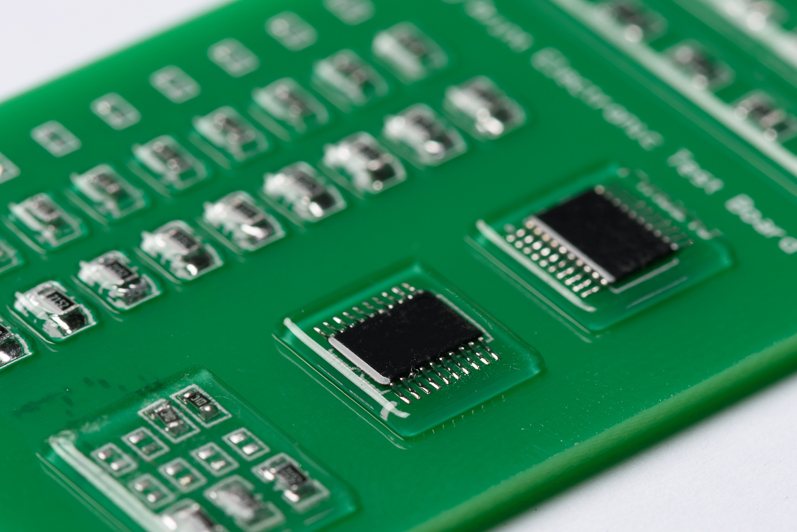

Whole area processing logic with image processing technology

Process Flow

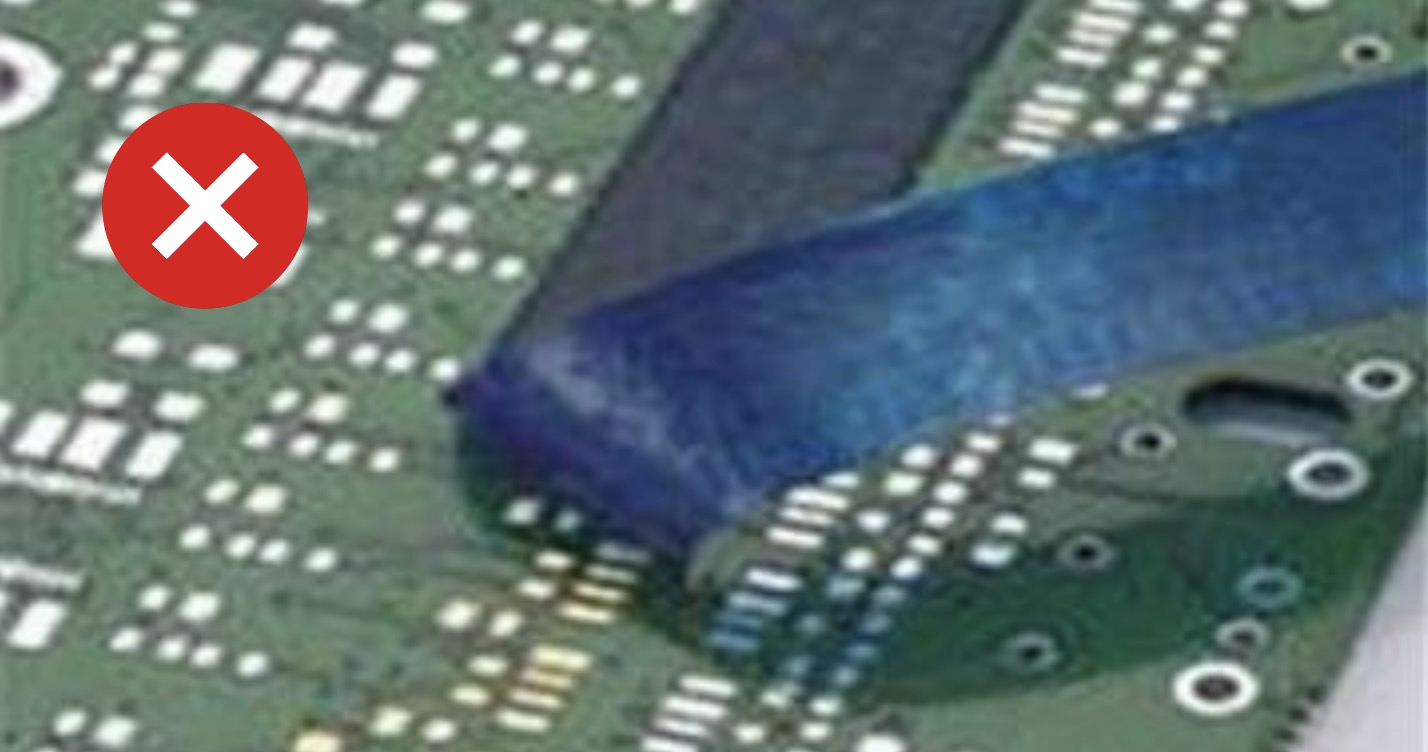

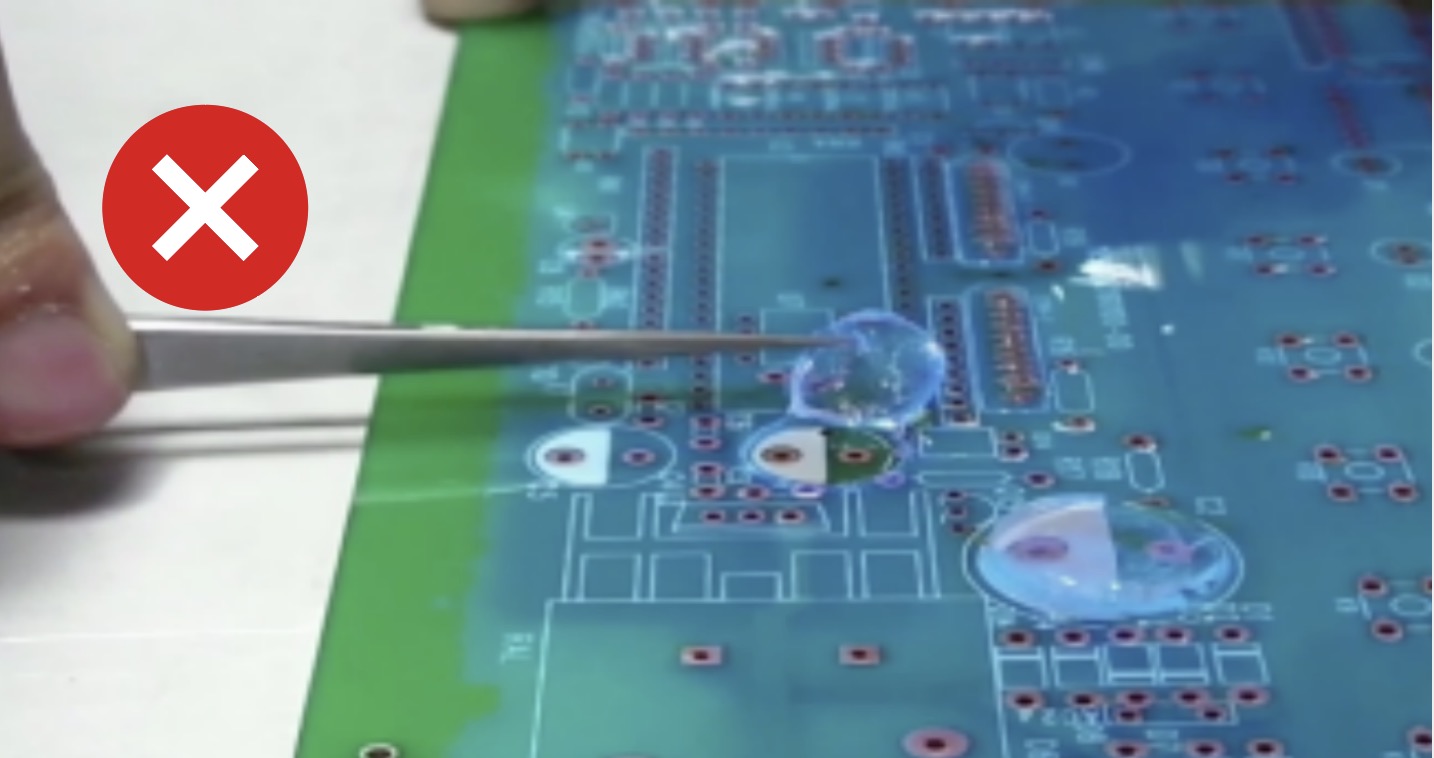

No need masking tape

No need masking glue

Dispensing, Coating

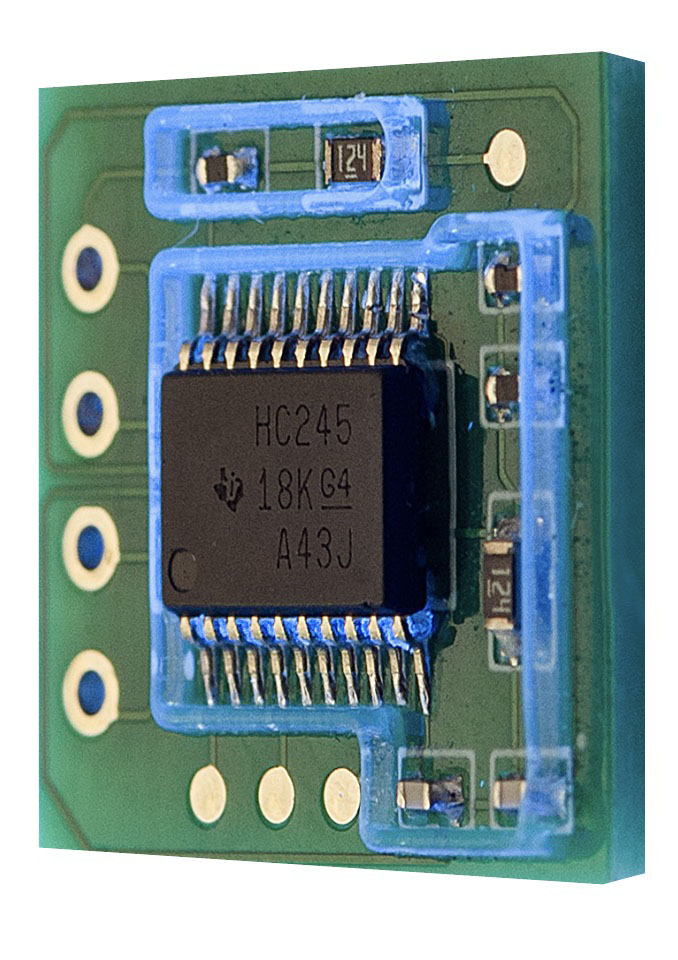

implemented on one device, realizing different protection levels

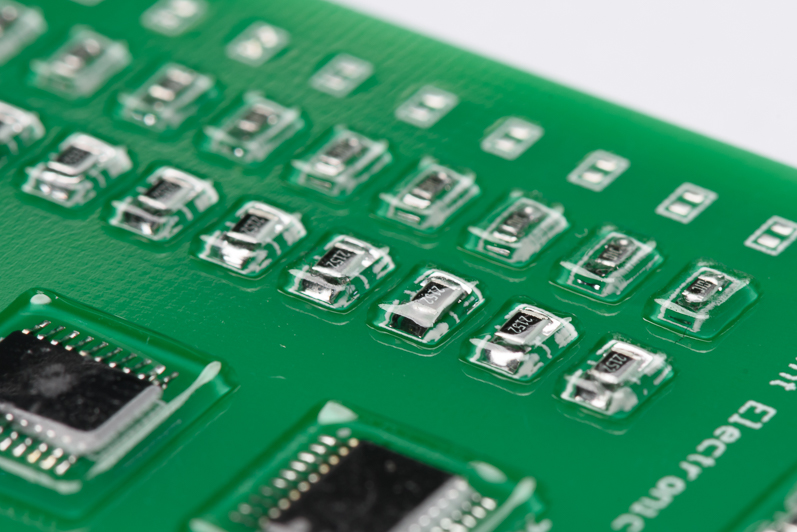

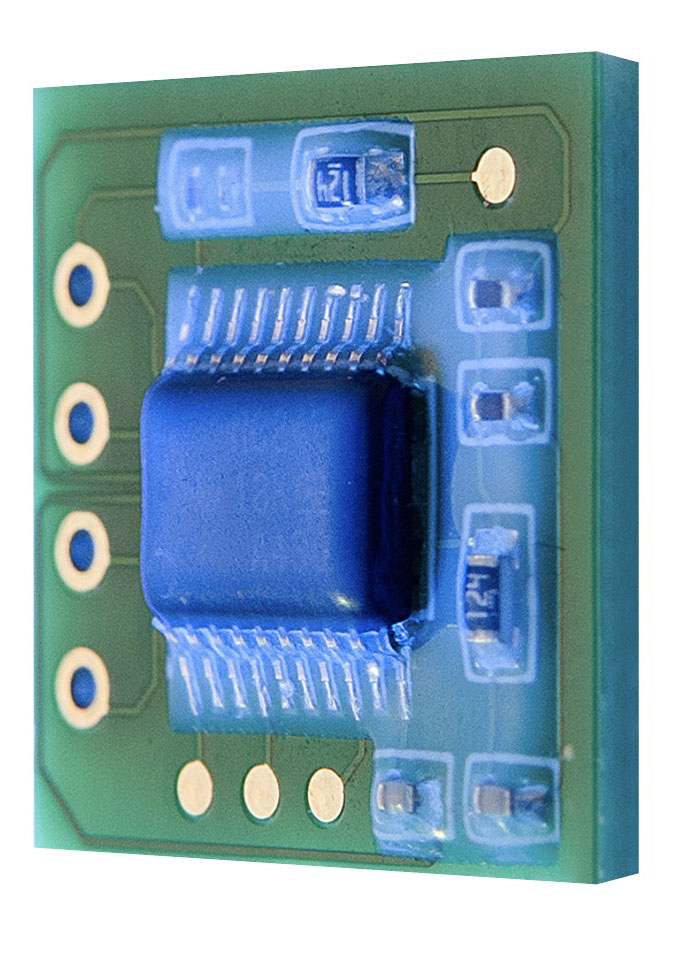

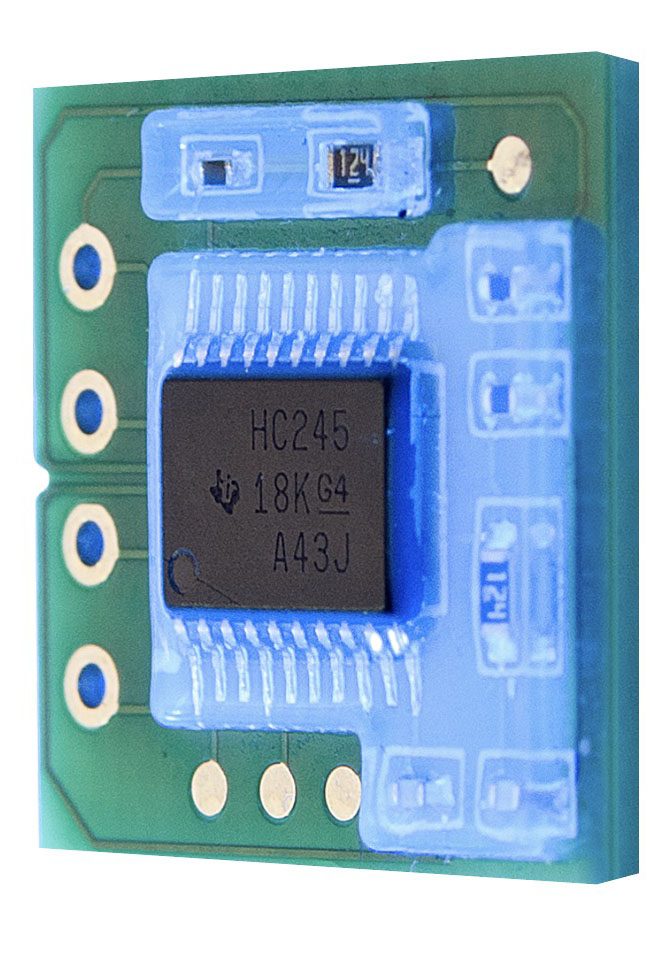

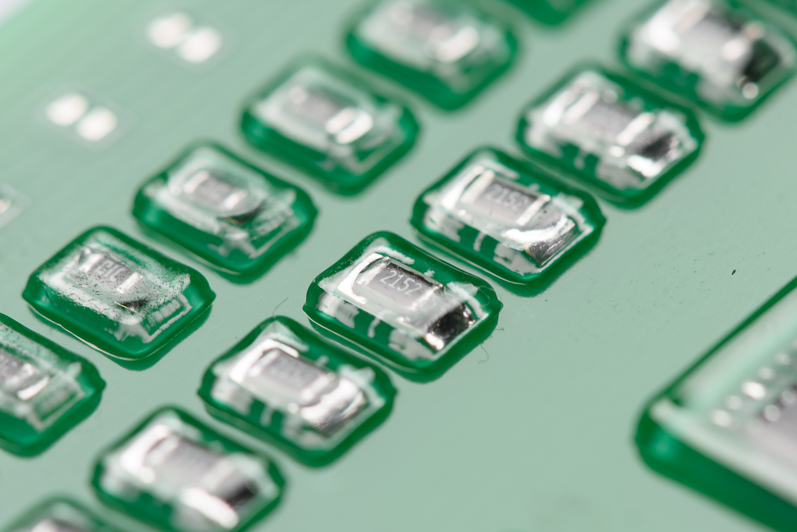

Thin layer coating

general protection

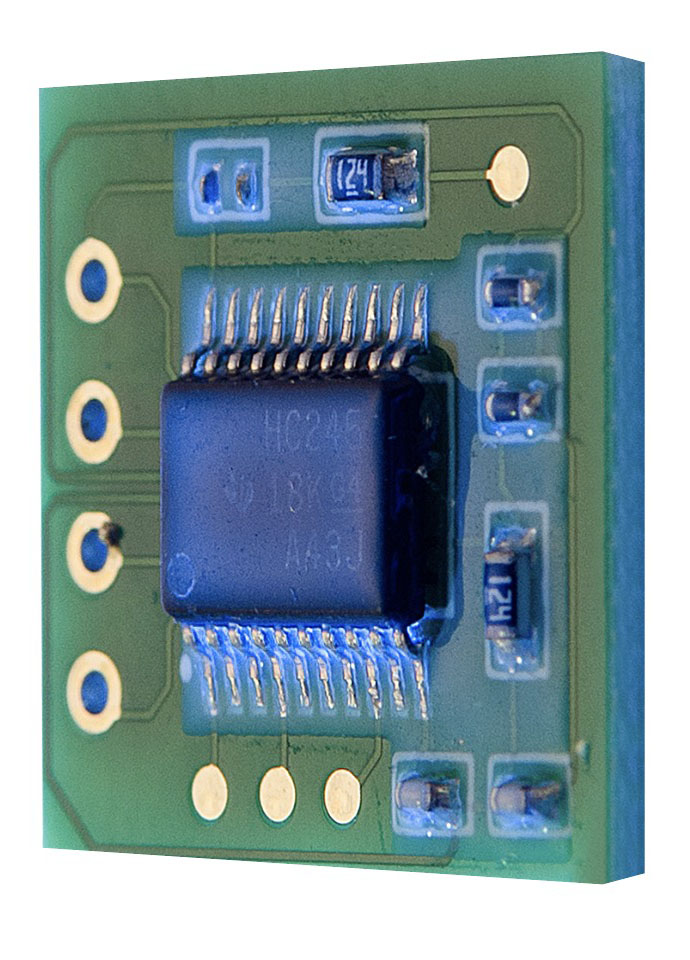

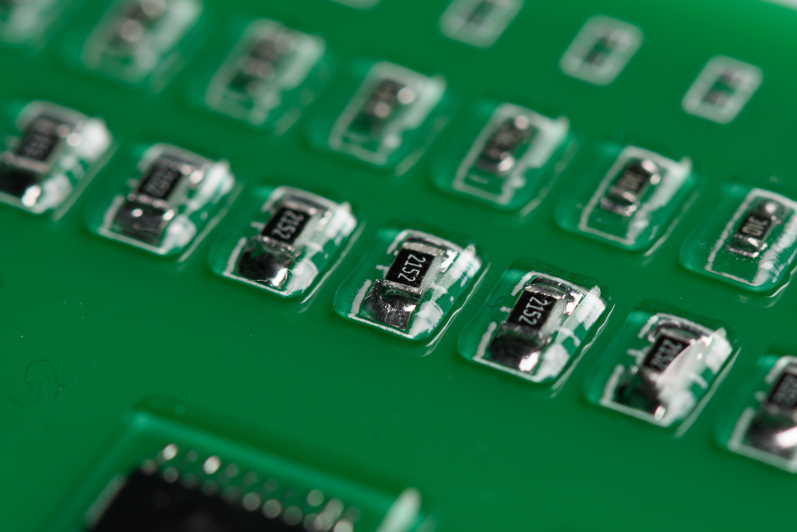

Thick layer coating

high-grade protection

Fence + filling

with same UV glue

Separate fence

fill with any glue

Actions speak louder than words

"The production process that used to take a few minutes, now only takes a few seconds."

The protection area is 10*10mm

glue can be saved at least 1/3

Auxiliary process

no need to masking, no need wait for curing

60 μm thickness is required

accuracy and thickness can be guaranteed

Environmental

no solvent volatilization and no need special protection

Production efficiency

only need 10s, efficiency increased dozens of times

Time is money, especially for the busy SMT production line. Although PCBA protection is a later process, the efficiency and effectiveness directly affect the delivery cycle and yield of PCBA. This is especially true for mass and multi variety production lines. PCBA needs to be coated for many times in order to meet the protection requirements. If you want to get a thicker coating, the conformal coating needs to be obtained by applying two thinner coatings, and the second layer must be applied after the first layer is fully cured. It takes time to cure completely. The digital packaging process is different. UV-Led is cured with follow-up while spraying, and the second layer can be sprayed immediately with controllable thickness.

PCBA packaging protection is completed by a more accurate and simplified process, which does not need to wait for curing and occupy the curing site. This is especially true for a large number of circuit boards that need protection. "Some of these batches may occupy the workshop for several days, so it is very important to save a few minutes per board."

Choosing a reliable process is also an improvement to the quality of the product.

01

High precision nozzle driven by image software

02

Mark point recognition system

03

UV-Led follow curing device

04

Ink cartridge circulation system

05

Temperature control system

06

High reliable 4-axis motion platform

Freely control the glue thickness to achieve higher precision packaging protection

After the UV glue is sprayed, the UV-Led is follow up to solidified automatically,

and the 2nd layer can be sprayed immediately.

The thickness of the single layer is 25 microns,

and the stacking thickness of the layers is controllable.

The process is safe and environment-friendly without waste water and waste gas

No water pollution

No solvent evaporation

No need special protection

Low energy consumption

Green material

Environment friendly

All rights reserved. No reprint without permission. 京ICP证000000号

All rights reserved. No reprint without permission. 京ICP证000000号