- NEEQ: 837355

- To be a global leader in overmolding protection industry.

Low Pressure Injection molding

Solution Has Been with You for Decades.

From the daily use of mobile phone charging line, LED lighting, computers, smart bracelet, to SCR system for the national VI environmental protection, and VR glasses, new energy vehicles which are the trend of science and technology, Low Pressure Injection Molding Solution has been successfully applied already.

We Redefine Industry Standards

KONIG has accumulated experience in low pressure injection molding for decades, and has developed the melt unit with all intellectual property rights and core patents. All the electronic components certified by EU quality system, which not only ensures the performance and stability, but also greatly improves the durability of the equipment.

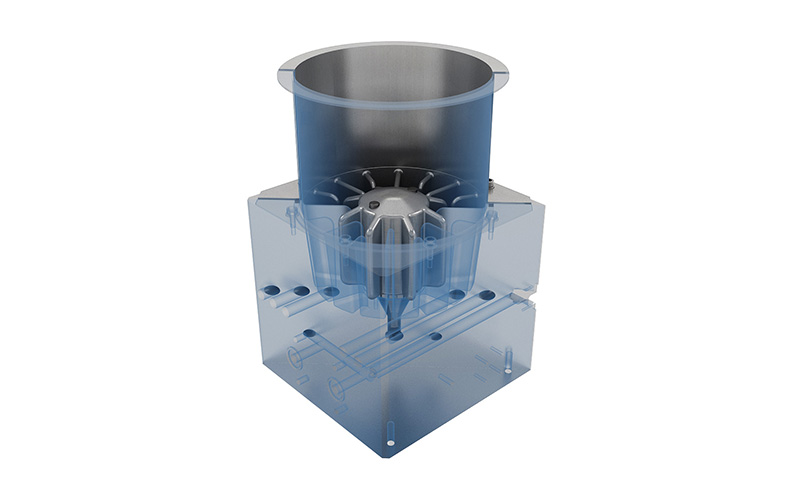

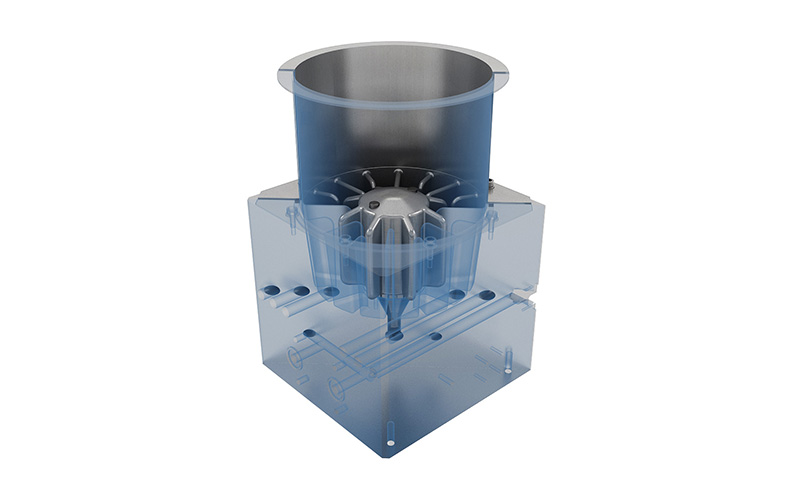

CNC MarkingWith CNC integrated molding, the utilization rate of heat energy by 2 times(patented); with four layer Teflon spraying, the friction coefficient is only 0.05; the anti carbonization of glue is improved, more wear-resistant and easier to clean.

CNC MarkingWith CNC integrated molding, the utilization rate of heat energy by 2 times(patented); with four layer Teflon spraying, the friction coefficient is only 0.05; the anti carbonization of glue is improved, more wear-resistant and easier to clean. Gradient Temperature ControlHelp to anti material carbonize, only melt the bottom of material, and the top is still granular. Continuous glue supply rate is no less than 38g/min with no waiting.

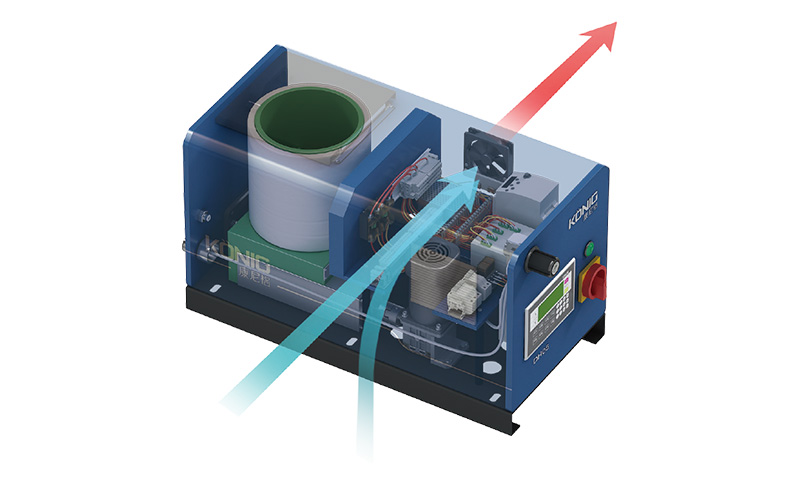

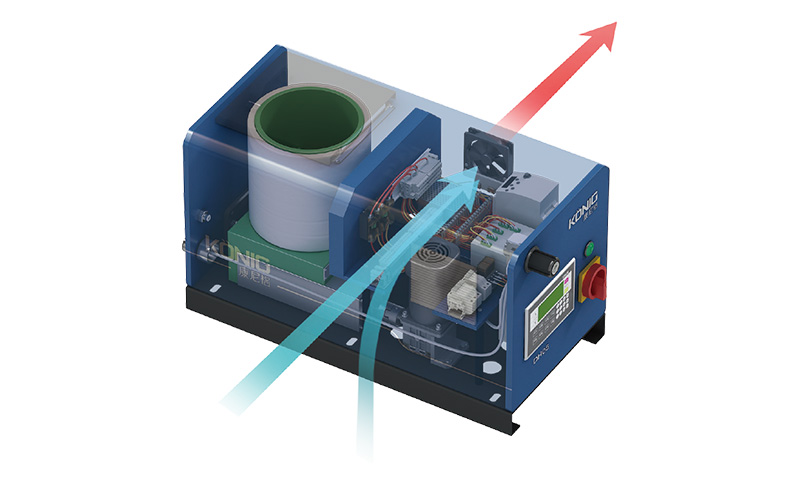

Gradient Temperature ControlHelp to anti material carbonize, only melt the bottom of material, and the top is still granular. Continuous glue supply rate is no less than 38g/min with no waiting. Air Convection TechnologyTo ensure the normal working temperature of electrical system. The special fiber insulation layer can firmly lock the heat energy of the cylinder, which is more efficient and energy-saving.

Air Convection TechnologyTo ensure the normal working temperature of electrical system. The special fiber insulation layer can firmly lock the heat energy of the cylinder, which is more efficient and energy-saving. HoseKJ22 Hose high temperature resistance, accurate temperature control, temperature difference between inlet and outlet is ± 2 ℃.

HoseKJ22 Hose high temperature resistance, accurate temperature control, temperature difference between inlet and outlet is ± 2 ℃. Injection NozzleKG40 injection nozzle, non-penetrating adhesive, high reliability. The cycle time up to 1.2 million times with precision pressure control.

Injection NozzleKG40 injection nozzle, non-penetrating adhesive, high reliability. The cycle time up to 1.2 million times with precision pressure control. Gear PumpKP25 gear pump, compact structure, excellent design brings precise measurement and stable glue output, which is no less than 8g/R.

Gear PumpKP25 gear pump, compact structure, excellent design brings precise measurement and stable glue output, which is no less than 8g/R.

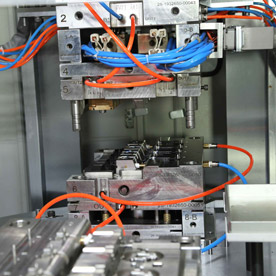

Flexible with Different Platforms

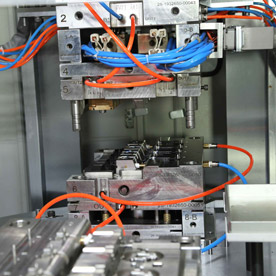

High adaptability design can adapt with different platforms according to different product characteristics.

-

Vertical Single/Double Nozzle

● Vertical injection, larger application space;

● Double nozzle injection, suitable for products with large amount of adhesive.

-

Side Single/Double Nozzle

● C-shaped layout, suitable for wiring harness products;

● Double station, higher production efficiency.

-

Left and Right Shifting Mode

● One upper die and two lower dies, whichis stable and efficient.

-

Customized Platform● Cooperate with customer's on-site production path, can join automatic production line.

KONIG LPIM Equipment Family

-

Equipment Datasheet and Technical Introduction

-

For the Production of Customers Escort

Drafting unit of chemical industry standard <Hot melt adhesive for low pressure injection molding encapsulation> Standard No.: HG/T5051-2016-

All rights reserved. No reprint without permission. 京ICP证000000号

All rights reserved. No reprint without permission. 京ICP证000000号

Service Hotline +86-512-52478847 | Support:ibrand |

All rights reserved. No reprint without permission. 京ICP证000000号

All rights reserved. No reprint without permission. 京ICP证000000号