-

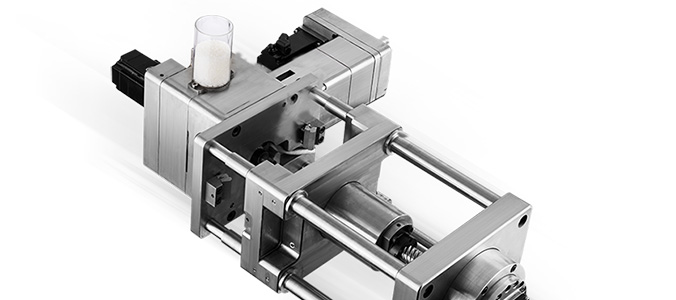

Material Plasticizing System

● The material is transferred from hopper to the spiral and curved disks, the two disks interact to friction/move the material from the outside to the inside;

● The depth of the curve groove gradually becomes shallow from outside to inside, and the material is compressed and plasticized, and the gas is removed at the same time;

● The plasticizing temperature can reach 430 ℃, and the plasticized material climbs to the center of the screw bythe Wiesenberg effect and is transported to the mold through the hot nozzle.

-

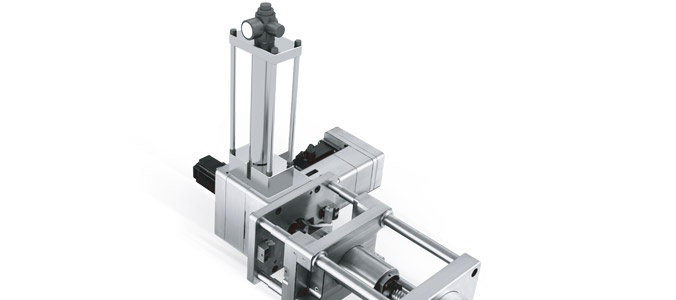

Hot Runner Molding System

● The injection pressure, time and speed can be adjusted independently;

● The micro products are milligram level. For general injection, only about 10% of the melt material is actually used even after optimization;

● KONIG equipment with hot runner integration technology can shorten the flow channel andreduce the waste basically; and the hot runner no need to be replaced with the mold, which simplifies the mold design and reduces the mold cost.

-

Mold Temperature Control System

● The mold temperature is controllable at all stages of injection;

● The mold temperature can be adjusted according to the different characteristics of materials;

● The cavity can be filledrapidly by increase the mold temperature during the injection process;

● The mold temperature can be reduced quickly to help product molding and ejection.

-

Production Management System

● Powerful production management function;

● Molding process is visualization andpartscan be counted;

● Mold datacan be saved, such as temperature, pressure etc.

All rights reserved. No reprint without permission. 京ICP证000000号

All rights reserved. No reprint without permission. 京ICP证000000号