- NEEQ: 837355

- To be a global leader in overmolding protection industry.

A creative technology makes injection

more handy & efficient.

Just for Micro Precision Products, is ideal to develop new projects or test new materials.

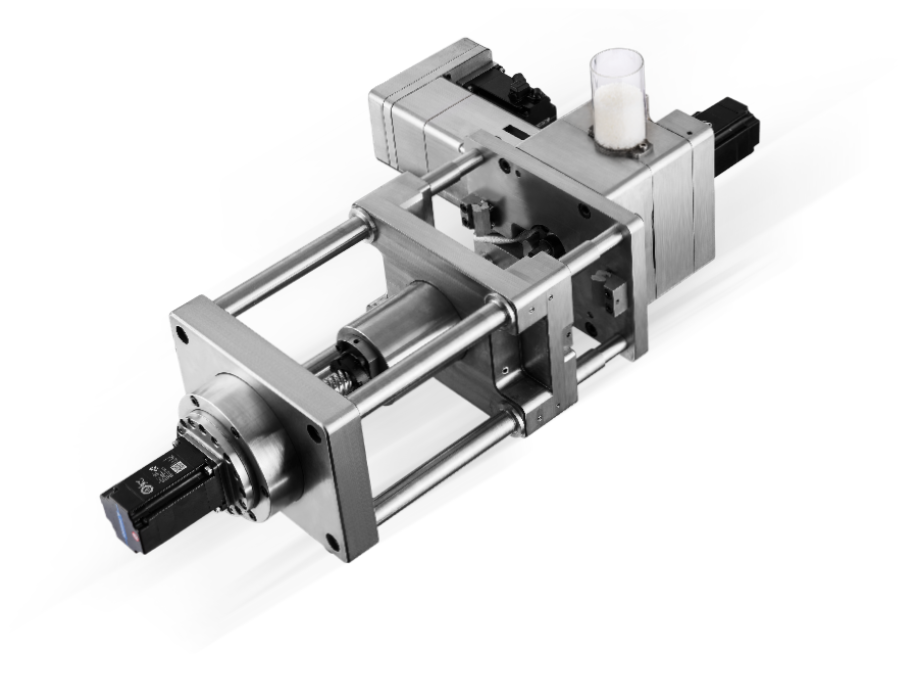

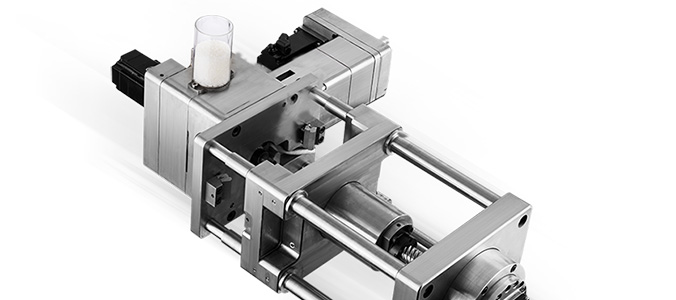

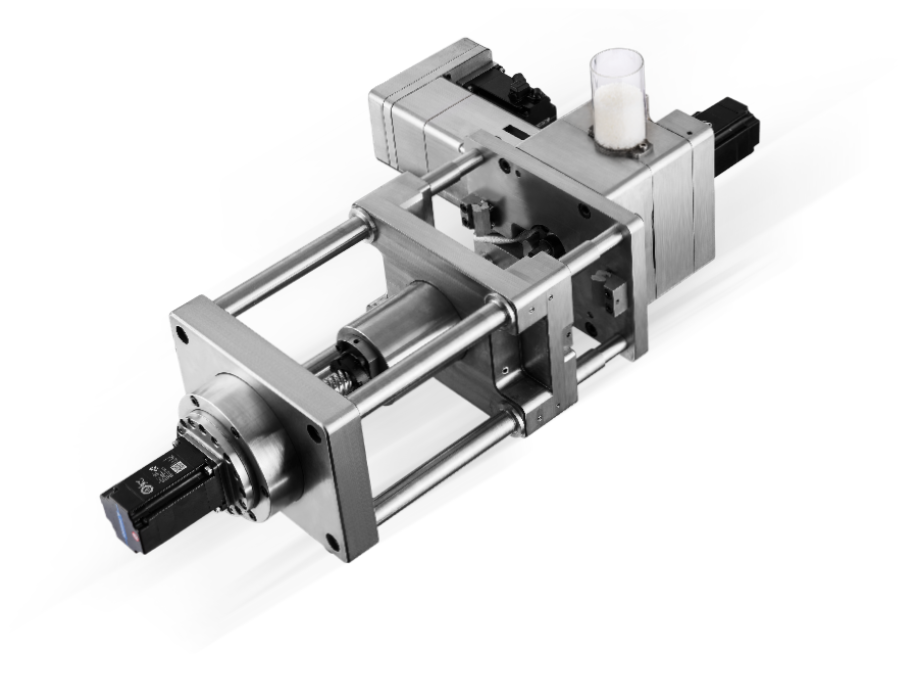

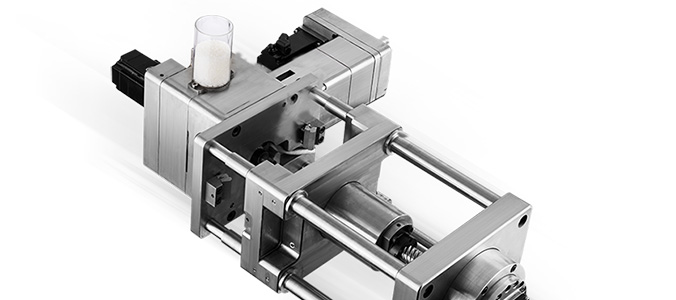

KM1600

For Engineering

Plastics

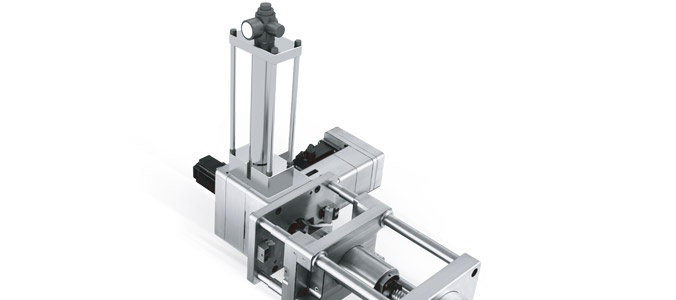

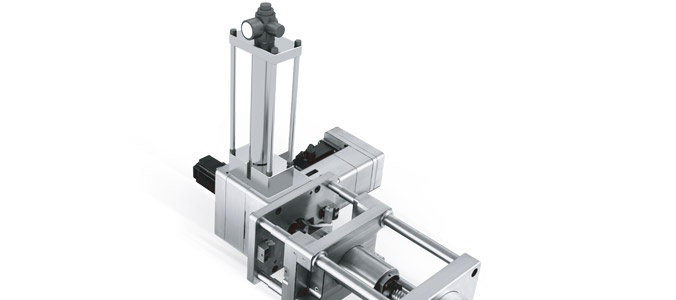

KM1600-LSR

For Liquid

Silicone Rubber

KE1600

For Hot

Melt Adhesive

-

Compact StructureInnovative flat screw to achieve the miniaturization, the equipment covers an area about 0.4㎡.

Precision InjectionJust little surplus material accumulated, especially suitable for injection molding production of expensive materials.

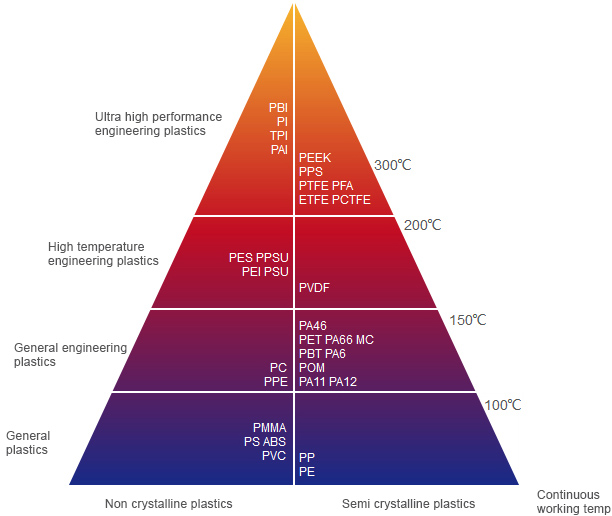

High FlexibilitySuitable for general engineering plastics and high performance engineering plastics such as PEEK.

Prevent CarbonizationThe plasticizing temperature can reach 420 ℃, the material can be used immediately after meltingwhich prevent carbonization.

Flexible for Multiple Materials

Use the standard particles, also suitable for high performance engineering plastics;

Meet the requirements of molding and precision, and cost saving for materials.

Suitable for:

ABS、PMMA、PS、PE、PP、PA、PC、POM、PBT、PET、PEI、PEEK、PPS、LCP、COP、PI、CIM、MIM, etc.

- Screw Diameter

- ¢80 mm

- Plunger Diameter

- ¢14 mm

- Screw Speed

- 30 rpm/min

- Screw Stroke

- Max 35 mm

- Injection Pressure

- 0~2060 bar

- Injection Speed

- 12.5 mm/sec*

- Max Injection Volume

- 5 cm3/sec

- Mold Clamping force

- 3 ton

- Mold Clamping Speed

- 12.6 mm/sec Rated 400W | 3000 rpm

- Mold Clamping Stroke

- 100 mm

- Die Size

- 160×130×96 mm

- Ejector Stroke

- 10 mm

- Hot Runner

- No.1658

- Hopper Capacity

- 0.2 liter

- Servo Motor

- 400 w×3 pc

- Power Conumption(excl.heat)

- 1300 w

- Electrical Source

- AC220 V

- Machine Size (HxDxW)

- 840×435×300 mm

- Machine Weight

- 98 kg

*Different power sources can be selected to obtain higher injection speed

-

Suitable for engineering plastics

-

Suitable for liquid silicone rubber

-

Suitable for hot melt adhesive

Drafting unit of chemical industry standard <Hot melt adhesive for low pressure injection molding encapsulation> Standard No.: HG/T5051-2016-

All rights reserved. No reprint without permission. 京ICP证000000号

All rights reserved. No reprint without permission. 京ICP证000000号

Service Hotline +86-512-52478847 | Support:ibrand |

All rights reserved. No reprint without permission. 京ICP证000000号

All rights reserved. No reprint without permission. 京ICP证000000号